Helping Clients Optimize and Improve Supply Chains with Real-Time Grainger Product Data Scraper

Feb 13

Introduction

In today's competitive industrial procurement landscape, maintaining accurate visibility into supplier catalogs, pricing fluctuations, and inventory availability is essential for operational excellence. This comprehensive case study examines how a multinational manufacturing enterprise leveraged Real-Time Grainger Product Data Scraper capabilities to transform their supply chain intelligence and procurement efficiency. The organization struggled with outdated product information, inconsistent pricing data, and limited visibility into stock availability across Grainger's extensive industrial catalog.

The company required robust capabilities to Scrape Grainger Product Data while navigating complex platform architectures and maintaining data accuracy across thousands of SKUs. Our tailored solution empowered them to capture critical product specifications, real-time pricing updates, and inventory status from Grainger's comprehensive marketplace, fundamentally transforming their procurement workflows, vendor negotiations, and cost management strategies.

By implementing our specialized extraction infrastructure, the client achieved remarkable improvements in procurement accuracy, operational efficiency, and cost savings, establishing a powerful data foundation for sustained competitive advantage in industrial sourcing.

The Client

Our client operates as a prominent manufacturing conglomerate with production facilities spanning twelve international locations, serving diverse industries through thirty-five years of engineering innovation. Despite their impressive manufacturing capabilities, they encountered mounting challenges in managing procurement operations efficiently, particularly when competing against organizations utilizing advanced Real-Time Grainger Product Data Scraper technologies to optimize their supply chain performance.

"Before partnering with Web Data Crawler, our procurement team operated with fragmented visibility into Grainger's product catalog and pricing structures," explains the client's Supply Chain Director. "Manual tracking of product specifications and availability was inefficient and error-prone. Without effective systems for Automated Grainger Product Data Extraction, we couldn't identify cost-saving opportunities or respond quickly to inventory fluctuations. We were losing significant value to competitors with superior procurement intelligence."

Adopting our advanced data capture platform revolutionized the client's sourcing approach, delivering unprecedented insight into industrial product markets and enabling strategic decision-making across their global procurement operations.

Within eight months of implementation, they achieved:

- 42% improvement in procurement cost efficiency

- 34% reduction in stockout incidents

- 31% enhancement in supplier negotiation outcomes

- 28% decrease in manual data gathering efforts

The Core Challenges

The client encountered multiple critical obstacles that compromised their procurement effectiveness and supply chain optimization:

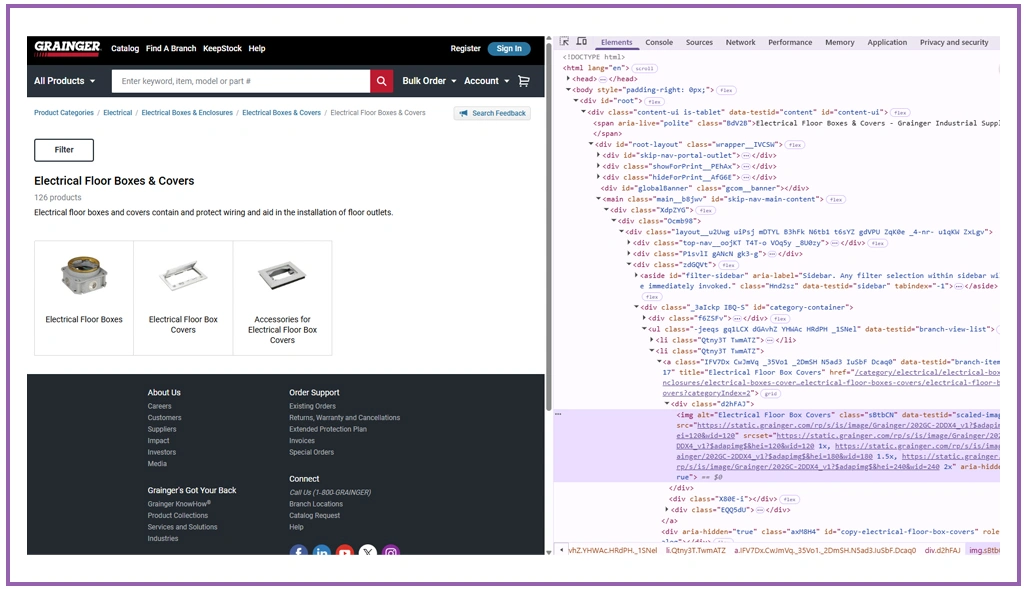

Access Complexity Barrier

Establishing reliable methods to Scrape Grainger Product Details at Scale was obstructed by sophisticated authentication mechanisms, dynamic content loading, and protective security measures that prevented consistent data access.

Catalog Standardization Hurdle

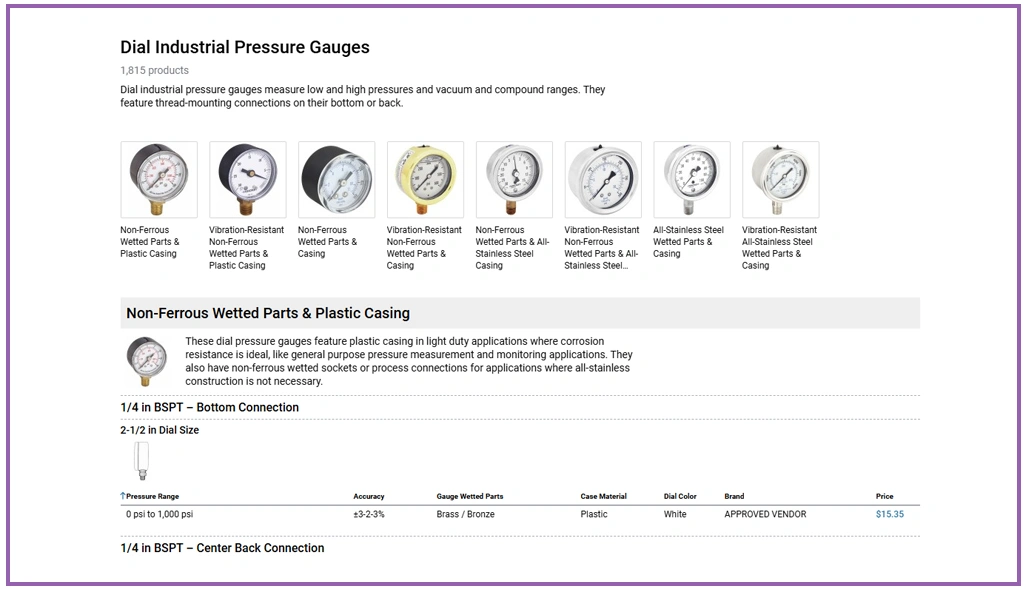

Normalizing diverse product information proved challenging due to inconsistent catalog structures across industrial categories, specification formats, and pricing models, creating significant E-Commerce Datasets integration difficulties.

Volume Management Constraint

Without efficient capabilities to Extract Grainger Pricing and Stock Availability Data, processing massive product catalogs across multiple categories hindered timely analysis, resulting in delayed procurement decisions and missed cost-saving opportunities.

Main Client Requirement

The client specifically needed a comprehensive solution that could continuously monitor Grainger's extensive industrial catalog, capture granular product specifications, track real-time pricing changes, and provide instant visibility into stock availability across their high-priority procurement categories while maintaining data accuracy and system reliability.

Smart Solution

After conducting thorough analysis of client requirements and technical specifications, we engineered a customized platform utilizing advanced extraction methodologies designed specifically for Grainger's marketplace infrastructure.

ProcureSync Intelligence Engine

The CatalogVision Framework enables Grainger Inventory Data Extractor functionality using adaptive browsing technology, intelligent request distribution, and anti-detection mechanisms to monitor product specifications, pricing variations, and availability status across industrial categories.

Data Harmony Platform

The SpecAlign System powers standardized data integration by unifying catalog formats, automating product classification, analyzing pricing patterns, and delivering structured insights for strategic procurement optimization.

Strategic Advantage Hub

The SourceIQ Platform leverages to Extract Grainger Pricing and Stock Availability Data with machine learning algorithms, automated alerting systems, and competitive analysis tools to transform raw product information into actionable procurement intelligence.

Execution Strategy

We implemented a phased deployment approach to establish our solution for comprehensive catalog monitoring, emphasizing seamless integration and sustainable performance optimization throughout each phase.

Requirements Assessment Phase

We conducted a detailed evaluation of Grainger's platform architecture, defining integration parameters, performance benchmarks, and procurement intelligence goals to develop a customized implementation framework.

Infrastructure Development Stage

Utilizing advanced parsing technologies and Scraping API integration, we constructed a robust extraction infrastructure with standardized data schemas for seamless access across procurement, sourcing, and operations teams.

Quality Validation Cycle

Comprehensive testing protocols and accuracy verification confirmed system reliability and data integrity, with stress testing ensuring consistent performance during high-volume extraction periods and validating real-time accuracy.

Progressive Implementation Phase

We initiated deployment across priority product categories and procurement segments, incorporating team training with continuous monitoring and dedicated technical assistance to ensure smooth, scalable, cross-departmental adoption.

Enterprise Expansion Initiative

Extended data capture across comprehensive industrial categories with flexible infrastructure. Ongoing optimization and knowledge transfer ensured system adaptability for evolving procurement requirements and organizational priorities.

Impact & Results

The deployment of our Grainger intelligence platform generated substantial improvements across critical operational and strategic dimensions:

Cost Optimization Achievement

The client utilized Automated Grainger Product Data Extraction and refined sourcing strategies using intelligence-driven insights, dramatically reducing procurement expenses and strengthening vendor negotiation leverage.

Procurement Intelligence Transformation

By implementing Grainger Inventory Data Extractor capabilities, the client enhanced sourcing accuracy and offerings, revolutionized competitive analysis across product categories, and amplified their market positioning effectiveness.

Operational Efficiency Advancement

By deploying automated catalog monitoring infrastructure, the client eliminated manual research burdens, accelerated procurement response times, and redirected strategic resources toward innovation and enhanced supplier relationships.

Market Responsiveness Enhancement

With instant product availability intelligence, the client rapidly adapted to supply fluctuations, anticipated inventory changes, and synchronized procurement activities with operational demands and seasonal requirements.

Sustainable Competitive Positioning

Powered by predictive analytics and continuous marketplace monitoring, our solution delivered consistent strategic improvements, eliminated information gaps, and reinforced the client's foundation for enduring procurement excellence.

Final Takeaways

This success demonstrates how sophisticated data intelligence can generate transformative insights, driving superior performance in contemporary industrial procurement environments.

Intelligence Advantage Framework

Continuous access to comprehensive product catalog information creates strategic superiority by revealing pricing dynamics and availability patterns using tools to Scrape Grainger Product Details at Scale, maximizing cost-saving opportunities.

Integration Excellence Model

Embedding Enterprise Web Crawling technologies into established procurement workflows ensures real-time intelligence informs decision-making, elevating strategy execution across operational functions for manufacturing organizations.

Automation Efficiency Revolution

Automated catalog monitoring replaces time-consuming manual processes, amplifying efficiency in procurement operations and enabling teams to redirect attention from research to value creation through intelligence-driven strategic initiatives.

Adaptive Response Mechanism

Continuous monitoring supports agile procurement strategies by consistently aligning forecasting with marketplace dynamics, ensuring optimal responsiveness using live product behavior patterns and availability intelligence.

Data-Powered Leadership

Harnessing advanced extraction technologies, industrial organizations secure lasting advantages through proactive decisions shaped by emerging trends and intelligence-informed responses to evolving supplier landscapes.

Client's Testimonial

Implementing Fresh Food Market Insights via Farmers Choice Scraper has completely transformed our competitive intelligence approach. Web Data Crawler's platform delivered precise marketplace visibility that enabled evidence-based decisions replacing guesswork. Our Farmers Choice Foods Pricing Data Extractor capabilities and overall profitability improved substantially within months.

– Supply Chain Director, Regional Fresh Food Distributor

Conclusion

We understand the complex challenges industrial organizations face when managing procurement in dynamic supplier marketplaces. Our specialized Real-Time Grainger Product Data Scraper services are designed to deliver seamless, reliable, and comprehensive catalog intelligence for enhanced operational performance.

Our solutions enable you to achieve strategic advantages through Automated Grainger Product Data Extraction and strengthen your competitive position in industrial sourcing. Leveraging Grainger Inventory Data Extractor technologies, you can transform your procurement operations with actionable insights.

Contact Web Data Crawler today for an in-depth consultation and discover how our customized industrial catalog intelligence solutions can revolutionize your supply chain operations.